Loading... Please wait...

Loading... Please wait...Categories

- CLOSE OUT CLEARANCE, BLOW OUT SALE ITEMS

- Rebuildable Engine Blocks, Block Cores

- Add on payment, Special Item Order Option

- AMC

- BEARINGS, ROD & MAINS

- BUICK

- CADILLAC

- CAM BUTTONS & LOCK PLATES

- CHEVY BB, GEN 4, MARK IV

- CHEVY BIG BLOCK, GEN 5

- CHEVY VORTEC, V6 4.3

- CHEVY, BIG BLOCK, GEN 6/7

- CHEVY, LS SERIES, Gen III, Vortec, LS1, 3, 6, L92

- CHEVY, LT1, GEN II SBC

- CHEVY, GM GEN V/5, LT1, LT4

- CHEVY SMALL BLOCK GEN I

- CHEVY, VORTEC, 5.7 IRON CASTINGS, GEN II

- CHRYSLER, SMALL BLOCK 273-360

- CHRYSLER, BIG BLOCK, 383-440

- FORD, SMALL BLOCK, 289

- FORD, SMALL BLOCK 302 HO w/ E7, GT40P & GT40

- FORD, SMALL BLOCK, 302, 1969-85

- FORD SMALL BLOCK, 351W

- FORD 351 CLEVELAND

- FORD, FE 352, 360, 390, 410, 427, 428

- FORD, BIG BLOCK, 429-460

- FORD, 4.6, 5.4, 16 Valve

- FORD, 2.3, 140 4 Cylinder

- FORD 6.0 DIESEL

- FORD 6.9/7.4 DIESEL, IDI, POWERSTROKE

- FORD 351/400M

- FORD, BOSS 302

- FORD 239, 256, 262, 272, 292, 312 "Y" BLOCK

- FREEZE PLUGS, EXPANSION PLUGS

- GASKET SEALERS

- GUIDE PLATES, PUSHROD

- HARDWARE, ENGINE

- HARLEY DAVIDSON

- HEAD TO BLOCK DOWELS

- HEADS, NEW STOCK REPLACEMENT

- HEADS, PERFORMANCE

- IHC, INTERNATIONAL 6.9/7.3

- OLDSMOBILE, V8

- PONTIAC 455

- PONTIAC, 326-400

- PUSHRODS- OE Replacement Type

- PUSHRODS- Single Piece Hi-Perf Chromoly

- REAR MAIN SEALS

- PUSHROD LENGTH CHECKER TOOLS

- RETAINER & LOCK KIT

- RETAINERS, VALVE SPRING

- RING SETS

- ROCKER ARM PARTS, ALIGNMENT GUIDE, FULCRUM

- ROCKER STUD & GUIDE PLATE KITS

- ROCKER STUD, GUIDEPLATE & PUSHROD KITS

- STUDS, ROCKER ARM

- TOOLS, ENGINE ASSEMBLY TOOLS

- ROLLER ROCKERS

- VALVE GUIDES

- VALVE LOCKS (KEEPERS)

- VALVE SEAL FITTING SLEEVES

- VALVE SEALS 11/32"

- VALVE SEALS 3/8"

- VALVE SEALS 5.5mm

- VALVE SEALS 8mm & 5/16"

- VALVE SEALS, 5MM

- VALVE SEALS, 7mm

- VALVE SEALS, MOTORCYCLE

- VALVE SEATS

- VALVE SEATS- IMPORTS

- VALVE SPRING SHIMS

- VALVE SPRING CUPS

- VALVE SPRING LOCATORS

- VALVE SPRING KITS

- VALVE SPRING KITS WITH STAINLESS VALVES

- VALVE SPRINGS

- VALVES, STAINLESS STEEL

- WATER BYPASS TUBES

Popular Brands

Become a member

- Home

- VALVE SPRING SHIMS

VALVE SPRING SHIMS

VALVE SPRING SHIMS are designed to reduce valve spring installed height. They are used to establish the distance between the spring base and spring retainer, known as "target" installed height. Setting up valve spring installed height is vital to obtaining optimum spring performance and should not be assumed correct. Every application should be measured and shimmed as required.

General installed height tolerances are: -.010" to + .005"

Several manufacturers offer measuring tools known as "Valve Spring Height Micrometers" Also known as a "Height Mic". For those who plan on building more than one engine in their lifetime, should have an installed height mic in their toolbox.

Although less accurate, D.I.Y.er's can make up their own measuring rod from a 16/20 penny nail cut to size. An pair of calipers are required to properly establish the rods length. Cut the nail slightly longer then grind the ends with a slight radius. Rounded ends are required or the results will not be accurate.

We offer shims in mostly hardened steel. High Spring Pressures will always require hardened shims. Hardened shims go through a special heat treat process which makes them resistant to wear.

Our hardened shims come in two different colors, Blue and Black.

Buyers are attracted to standard shims because they are less expensive than their hardened counterpart, normally half price but they will wear down from increased spring pressure which will populate the engine oil with metallic particulate.

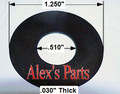

Our Valve Spring Shims come in three different thickness's.

We normally carry them in:

- .060"

- .030"

- .015"

- A kit with all three sizes

We list spring shims two ways; application and size. Application coverage will only display popular domestic applications. If you do not see your application, we suggest measuring the spring base to determine which shim will fit under your spring. If this is not possible, you can e-mail us for an suggestion. We will try to look it up for you. Taking a measurement is always best as some factory heads may have been previously machined for different diameter springs.

FITMENT: Spring shims are not required to be the same diameter as the spring. They can be larger as well as smaller on the outside diameter. It is acceptable for the spring to overhang the shim by a certain amount. Springs can be as much as .100" larger [.050" per side overhang] than the shim. Naturally, the shim can be larger than the spring as long as it fits the heads spring base. What is important is for the shim to fit on the spring base so it can sit all the way down.