Loading... Please wait...

Loading... Please wait...Categories

- CLOSE OUT CLEARANCE, BLOW OUT SALE ITEMS

- Rebuildable Engine Blocks, Block Cores

- Add on payment, Special Item Order Option

- AMC

- BEARINGS, ROD & MAINS

- BUICK

- CADILLAC

- CAM BUTTONS & LOCK PLATES

- CHEVY BB, GEN 4, MARK IV

- CHEVY BIG BLOCK, GEN 5

- CHEVY VORTEC, V6 4.3

- CHEVY, BIG BLOCK, GEN 6/7

- CHEVY, LS SERIES, Gen III, Vortec, LS1, 3, 6, L92

- CHEVY, LT1, GEN II SBC

- CHEVY, GM GEN V/5, LT1, LT4

- CHEVY SMALL BLOCK GEN I

- CHEVY, VORTEC, 5.7 IRON CASTINGS, GEN II

- CHRYSLER, SMALL BLOCK 273-360

- CHRYSLER, BIG BLOCK, 383-440

- FORD, SMALL BLOCK, 289

- FORD, SMALL BLOCK 302 HO w/ E7, GT40P & GT40

- FORD, SMALL BLOCK, 302, 1969-85

- FORD SMALL BLOCK, 351W

- FORD 351 CLEVELAND

- FORD, FE 352, 360, 390, 410, 427, 428

- FORD, BIG BLOCK, 429-460

- FORD, 4.6, 5.4, 16 Valve

- FORD, 2.3, 140 4 Cylinder

- FORD 6.0 DIESEL

- FORD 6.9/7.4 DIESEL, IDI, POWERSTROKE

- FORD 351/400M

- FORD, BOSS 302

- FORD 239, 256, 262, 272, 292, 312 "Y" BLOCK

- FREEZE PLUGS, EXPANSION PLUGS

- GASKET SEALERS

- GUIDE PLATES, PUSHROD

- HARDWARE, ENGINE

- HARLEY DAVIDSON

- HEAD TO BLOCK DOWELS

- HEADS, NEW STOCK REPLACEMENT

- HEADS, PERFORMANCE

- IHC, INTERNATIONAL 6.9/7.3

- OLDSMOBILE, V8

- PONTIAC 455

- PONTIAC, 326-400

- PUSHRODS- OE Replacement Type

- PUSHRODS- Single Piece Hi-Perf Chromoly

- REAR MAIN SEALS

- PUSHROD LENGTH CHECKER TOOLS

- RETAINER & LOCK KIT

- RETAINERS, VALVE SPRING

- RING SETS

- ROCKER ARM PARTS, ALIGNMENT GUIDE, FULCRUM

- ROCKER STUD & GUIDE PLATE KITS

- ROCKER STUD, GUIDEPLATE & PUSHROD KITS

- STUDS, ROCKER ARM

- TOOLS, ENGINE ASSEMBLY TOOLS

- ROLLER ROCKERS

- VALVE GUIDES

- VALVE LOCKS (KEEPERS)

- VALVE SEAL FITTING SLEEVES

- VALVE SEALS 11/32"

- VALVE SEALS 3/8"

- VALVE SEALS 5.5mm

- VALVE SEALS 8mm & 5/16"

- VALVE SEALS, 5MM

- VALVE SEALS, 7mm

- VALVE SEALS, MOTORCYCLE

- VALVE SEATS

- VALVE SEATS- IMPORTS

- VALVE SPRING SHIMS

- VALVE SPRING CUPS

- VALVE SPRING LOCATORS

- VALVE SPRING KITS

- VALVE SPRING KITS WITH STAINLESS VALVES

- VALVE SPRINGS

- VALVES, STAINLESS STEEL

- WATER BYPASS TUBES

- Home

- VALVE SPRING KITS

- Max Output I, Drop in style Beehive Valve Spring Kit, .580" Lift, Ford 351 Cleveland w/ Hyd Flat Tappet Cam, Ships 30 days after order.

- Home

- FORD 351 CLEVELAND

- Max Output I, Drop in style Beehive Valve Spring Kit, .580" Lift, Ford 351 Cleveland w/ Hyd Flat Tappet Cam, Ships 30 days after order.

Max Output I, Drop in style Beehive Valve Spring Kit, .580" Lift, Ford 351 Cleveland w/ Hyd Flat Tappet Cam, Ships 30 days after order.

Product Description

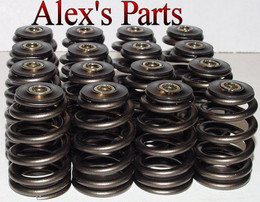

Beehive Spring Kit for 351 Cleveland

Max Output I, .580" Lift Beehive Spring Kit, 351C Flat Tappets & Single Groove Valves

Fitment: Ford 351 Cleveland

Processing Time: Current processing time is around 30 days. This means your order will ship around 30 days after being placed.

Here is the new .580" lift beehive kit for 351C.

With their 1.72/1.73 ratio rockers, Cleveland engines produce a lot of lift, even with mild cam profiles.

This kit is intended to be used with hyd flat tappet cams in 351 Cleveland engines w/ single groove valves.

Good up to .580", these beehives fit right onto the stepped spring base Ford used on so many Cleveland engines.

Since this kit is designed to be used with single groove valves, they won't work with stock multi groove valves.

Proud to say, this is another Alex's Parts exclusive- made up to our specifications. We looked at the various beehive springs currently available from all the cam companies and none of them were suitable for this application so we went ahead and had PAC produce them for us.

Check out the features:

- Made in the USA

- Accepts up to .580" Lift at the valve

- 105 Lbs Seat Pressure for Hyd Flat Tappet Cams

- Parts included: Chromoly Steel Beehive Retainers, Beehive Springs and Hardened Locks

- Fits 351 Cleveland w/ single groove valves (will not fit stock multi groove valves)

- Spring seat machining is not necessary, the spring fits OE iron heads w/ a stepped spring base

- If desired, the kit can be used with umbrella seals, they fit inside these springs without a problem but we recommend going with .500" positive seals for better oil control. If the heads are off the engine, have the guides machined to .500" and use the "Add positive valve seals, 11/32" X .500"

Add-On Options:

- Premium Viton Umbrella Seals (Our premium viton valve seals are the finest available anywhere. Why settle for lower grade gasket company seals?)

- Premium Positive Viton Valve Seals. (Guide Machining required; guides must be machined to .500")

- Hardened Spring Shim Pack, Includes: 16 each of: .030" and .015" shims

Average Load Specifications:

- Seat Load: 105 Lbs @ 1.835" (Valve Closed) see note below*

- Open Load @ .500" Lift- 289 Lbs

- Open Load @ .525" Lift- 296 Lbs

- Open Load @ .550" Lift- 309 Lbs

- Open Load @ .580" Lift- 320 Lbs

Size and Other Specifications:

- Small End ID- .651"

- Small End OD- 1.050"

- Large End ID- 1.000"

- Large End OD- 1.400"

- Solid Height- 1.086"

- Spring Rate: 366#

- .580" Lift Range (plus a .060" minimum safety margin before solid height)

Can be used with a wide range of hyd flat tappet cam profiles from Mild to Hot. If you want to verify compatibility, feel free to use the contact us link and forward the lift and duration @ .050" figures or simply send us the brand and part number so we'll look it up. Let us know how you plan to run the engine and if it has boost. (daily driver/cruiser, street/strip use, turbo, supercharger, spirited hot street tire burner, circle track, etc.)

Pick up a beehive spring kit, all for around the same price the other guys charge for 16 beehive springs alone!

Our customers know we're very serious about our spring kits. Our quality can be compared to parts selling for well over twice the price. When you order from us, you're getting the best possible value available anywhere.

Average shipping delay is around 30 days after order date. If you need it quicker, be sure to order early or contact us about rush order option at a higher cost.

*Note- The seat load installed height spec in this listing is for reference only, please use the installed height specification included with the actual spring kit.

Questions & Answers:

- Q- How important is it to measure valve spring installed heights?

- A- Setting up installed heights is important for the following reasons:

- Measuring installed heights will assure the intended seat and open loads are achieved.

- Builders who want maximum performance will always measure their installed heights and add shims as needed to get the installed heights as close as possible to the target spec card included.

- Q- How close do I need to get the installed heights to the target height spec?

- A- As close as you can with a tolerance of minus .010" to plus .005" over target height. Once the engine is run, the locks will seat further into the retainer. This is a natural process, 7 degree hardware will wedge tight together and as this happens, the installed height will increase a very small amount so it's better to lean on the lower side of target height.

- Q- Will I need an installed height micrometer to set up the installed heights?

- A- Yes, in order to properly set up installed heights, a height micrometer suited for beehive springs will be required. It must also be capable to clearing Ford's stepped spring base. The mic must contact the same surface as the spring.

- Q- We have a beehive installed height mic which we used on another application- will it work on my Cleveland heads?

- A- That depends on the brand and model of the mic. Some height mics are designed for beehive springs and LS Chevy heads or for aftermarket heads with a large flat spring base. Mics for such applications will not clear the raised "step" on 351C heads.

- Q- How can I determine if the beehive mic we have will work on a Cleveland?

- A- Just measure the opening (bore) on the bottom of the mic. If the inside diameter measures 1.025" or larger, it should work.

- Q- Can I measure the installed heights with a machinist scale, snap gauges or calipers?

- A- Negative, this is not a viable option for the following reasons.

Calipers, snap gauges or a machinist scale will only work when the measurement is taken parallel to the valve stem and not at an angle. Since the heads stepped spring base is bigger than the retainer, these tools are not useful for this application.

- Q- My existing installed height micrometer has a stepped top surface which the beehive retainer enters into and contacts the bottom of the step below. The readings I'm getting are .150"+ more than my target installed height. Whats going on and how do I deal with this?

- A- This condition happens when an installed height mic designed for larger diameter retainers is used with a beehive set up. On common "cylindrical spring" installed height mic's, the shape of the top of the mic is intended to clear the first step of the retainer. Most beehive retainers are too small for Std installed height mic's and will fall into the counter bore which produces an inaccurate measurement.

- Q- Can't I just measure the depth of the counter bore of my Std installed height mic and figure this measurement into the equation?

- A- Technically Yes but this is not recommended simply because it's easy to get confused as to whether the measurement should be added or subtracted which often leads to acquiring the wrong final installed height. If you're going to do this, be sure to subtract the measurement.

- Q- How do I determine if the top side of my mic will work with a these beehive retainers?

- A- Just measure the inside diameter of the topside of the mic and compare it to the OD of the retainer. The retainer must sit on the top surface of the mic and not inside its counterbore.

- Q- Do I need hardened shims?

- A- Yes. Std shims are too soft and will break down during use. Std shims should not be used because as they wear down deposit fine metal particulate into the crankcase oil.

Have a unique question? Just use the contact us link.